Invention Coach:

Public Inventor(s):

Previous PIs:

Veronica Stuckey, Lisa Kotowski

Motivation:

A Simple, Reliable Valve Design

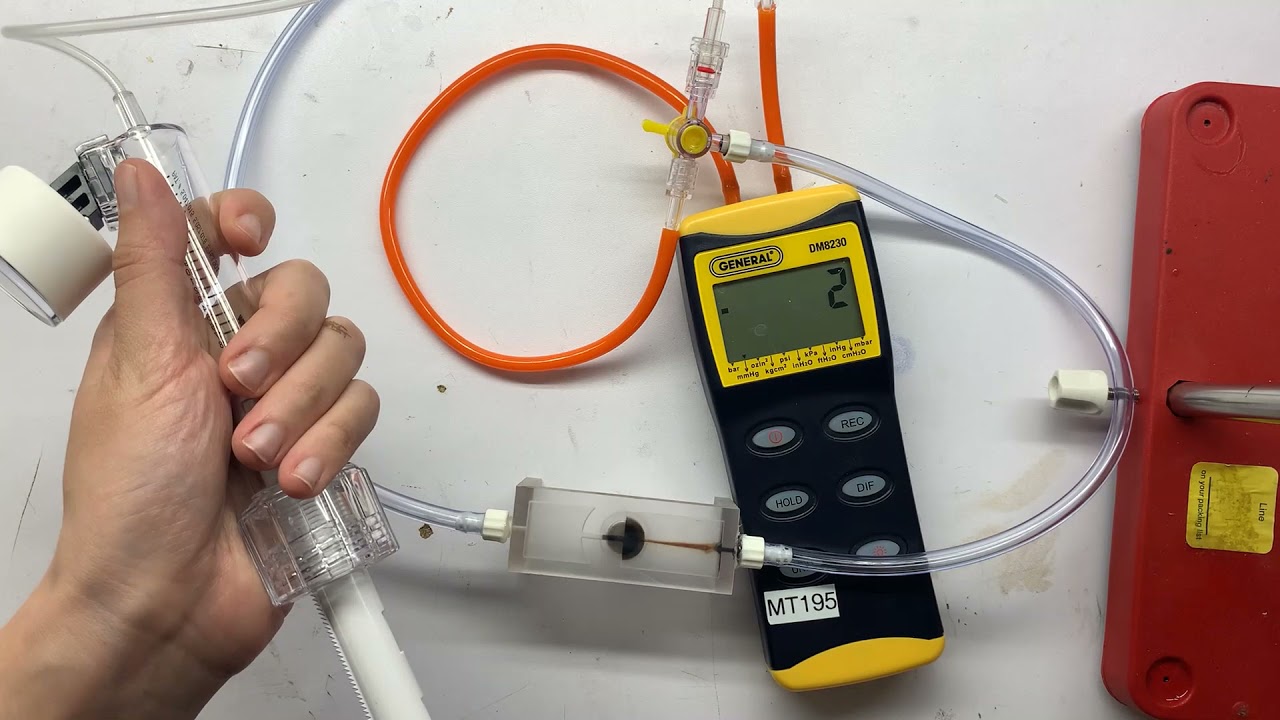

The Passive Ferrofluid Check Valve (PFCV) project aims to create a novel, passive one-way valve using ferrofluids with no moving parts. This design makes it ideal for lab-on-a-chip applications. Additionally, the valve’s simplicity and lack of mechanical components offer advantages in terms of reliability and ease of fabrication.

Valve Research Applications

The project explores the theoretical underpinnings of the valve and aims to improve its design and performance, potentially leading to new innovations in fluid control and pump systems with minimal mechanical complexity.

Story:

PFCV Development – A Surprising Breakthrough

The Passive Ferrofluid Check Valve began with a desire to create a valve with no moving parts that could easily integrate into lab-on-a-chip devices. After numerous experimental setbacks and a surprising breakthrough, the team discovered that ferrofluids—liquids that respond to magnetic fields—could be used to create a one-way valve that worked in the opposite direction of their initial assumptions.

This unexpected outcome led to a successful design that shows promise for efficient, passive fluid control in small-scale applications. The team continues to develop the project.

Related Open-Source Projects

If interested in learning more about our other projects, check the following pages for updates and volunteer opportunities:

Status:

Skills Needed

The FerroFluid Check Valve team is looking for new team members with the following backgrounds and skills:

- 3D drafting

- Simulation work in Solidworks

- Physics II principles

- Principles behind one-way valves for microfluidic devices

If interested in joining the project, please reach out to Robert L. Read, Volunteer Coordinator Miriam Castillo, or Volunteer Now.

Quarterly Goals

Collateral