Invention Coach:

Public Inventor(s):

Melanie Laporte, Harshit Kumar, Halimat Farayola, Enrique Ruiz, Horacio García, Silvia Karbid, Darío Hereñú, Kenton Robe, Sara J Barker, Nancy Merirts

Previous PIs:

Robert Read

Motivation:

A Portable Incubator

An Inexpensive Water Quality Solution

Water-borne disease is the leading cause of death globally. In 2019, it killed 3.4 million people – the majority being children. The first step in providing clean water is being able to verify that water is clean. There are many ways to assess water cleanliness. The standard way to do this is by culturing a sample on a nutrient with reagents, and incubation at physiological temperatures for 48 hours. This makes colonies visible, and the user can then count these colonies.

Though commonly used for food quality assessment, petrifilms provide a visually compelling, quantifiable, and inexpensive method for demonstrating water contamination. Normally, analysis is done in a laboratory setting due in large part to the requirement for incubation, which currently can only be done in large, expensive laboratory-grade incubators.

In developing countries, however, laboratory facilities are either unavailable or require transport of samples, which can delay analysis for hours or even days beyond EPA and WHO standards. To combat this problem, an Engineers Without Borders (EWB) team developed a portable incubator capable of incubating petrifilms for 48 hours at 37C while in the field. The Portable Programmable Incubator project is the next evolution of the original incubator and an offshoot of the Rapid E. Coli detection for Public Invention.

Overall Goals

Build the best, cheapest, most reliable, most portable incubator for detecting bacterial contamination on site and in the field, without having to send samples to a distant laboratory. While we are targeting the use of petrifilm incubation, this portable incubator technology can also be extended to applications beyond water quality assessment, enhancing the capacity for accessible laboratory efforts, regardless of facility and resource availability.

Minimum Requirements:

- Battery/Solar powered device capable of maintaining contents at a specified temperature for at least 48 hours

- Programmable temperature targets (between 30C to 42C)

- Data logging capability to facilitate operator review

- Reduced form factor for added portability as compared to the current generation.

Story:

The Moonrat II: A Three-Year Development

2023: A New Design

In 2023, the Moonrat II team began making changes to the initial version of the project, the Moonrat I.

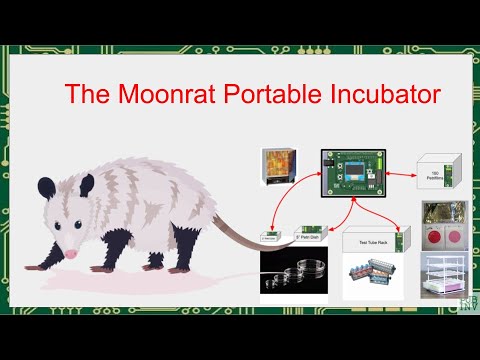

In a schematic for the new Moonrat, the team developed several main parts of the incubator. These included a Control Assembly, a Heater Assembly, an Incubation Assembly, heating pads, and a battery system.

The Control Assembly is in a detachable enclosure separate from the incubation chamber, while the Heater Assembly is mounted inside the Incubation Assembly, beneath the unit’s top. Finally, the team included a rechargeable battery with a recharging station to complete the Moonrat II design.

2024: Prototypes and Testing

After this design phase, in 2024, the Moonrat II team produced ten Printed Circuit Assemblies for the Control and Heater parts of the device, which were split between the USA and Mexico Moonrat II teams. They also began to design the Control Assembly’s enclosure.

In late 2024, the researcher Auja Bywater tested a prototype of the Moonrat II in the Galapagos Islands, and Dr. Robert Read tested one in Tanzania. This field testing resulted in several changes to the design of the heater board and the enclosure which the team has since implemented. See the project GitHub for more details.

2025: Completing the Project Build, Finalizing Design Files

In 2025, the team created a standalone schematic for a new heaterboard PCB, and they officially completed the mechanical design phase for the Moonrat II enclosure. All recent updates, including finalizing mounting holes, component spacing, and structural parameters, were committed.

The team test-printed the finalized design files and have updated the FreeCAD 3D models. During this process, they also updated the enclosure design to improve insulation and portability. In November 2025, the team completed the project build.

Related Open-Source Projects

If interested in learning more about other projects, check the following pages for updates and volunteer opportunities:

Status:

Skills Needed

The Moonrat II team is looking for new team members with the following backgrounds:

- 3D design

- Arduino programming

- Electro-mechanical design

- OpenSCAD programming

If interested in joining the project, please reach out to Robert L. Read, Volunteer Coordinator Miriam Castillo, or Volunteer Now.

Quarterly Goals

The team has multiple goals for 2026.

- Submit a paper to HardwareX for publication.

- Successfully complete and close the project

Collateral

https://zenodo.org/records/17694076

Related Sources:

EPA Guidelines: https://19january2017snapshot.epa.gov/sites/production/files/201511/documents/drinking_water_sample_collection.pdf

Original Incubator Paper – http://jhe.ewb.org.au/index.php/jhe/article/view/127